SUPPLYING THE BEST IN SEED CLEANING AND MILLING EQUIPMENT

Because the primary factor in this patented two-way mixing action is gravity, these mixers are the most efficient and cost effective equipment in the industry.

Download the complete

Scott Equipment’s Industrial Batch Mixers are designed to provide accurate mixing of all kinds of products, from fine powdered materials to coarse ground ingredients. They are durably constructed in either mild or stainless steel.

Please inquire for more information

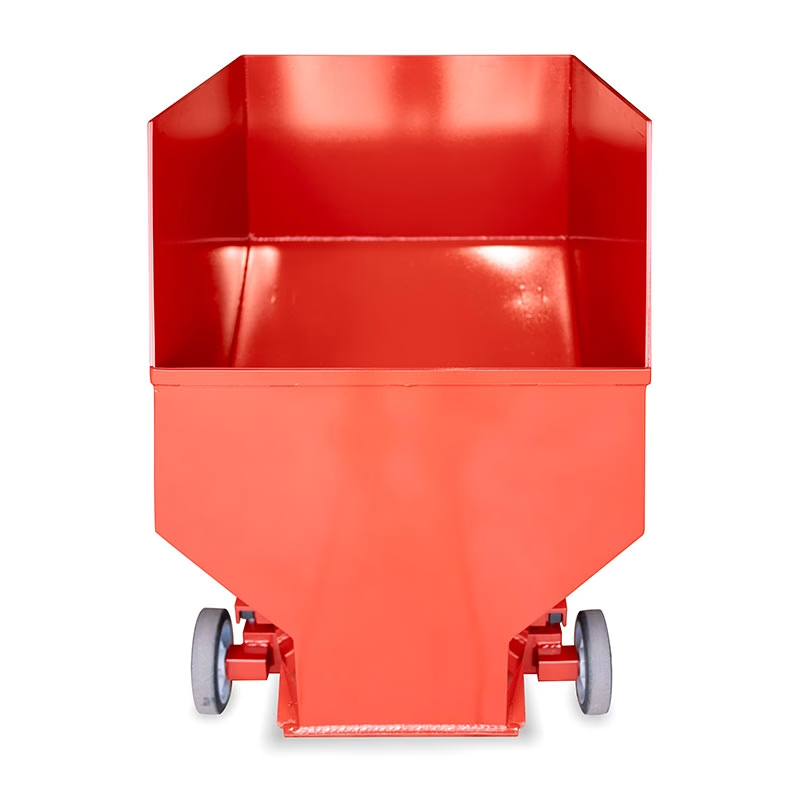

From fertilizers to grains, the B-TEK’s Portable Hopper Scale will improve mixing accuracy and save time/labor. This unit features a 12-cubic foot capacity hopper set on dual precision single point load cells. It has a capacity of 1,000 lb.

Download the complete

Product Sheet

With stainless construction, the AGBUILT Hammer Mill will stand the test of time grinding high moisture corn day in and day out. Its customized hub assures even wear to hammers and consistent particle size.

These mills are capable of handling 34 to 1250 lbs./min.

Download the complete

Product Sheet

Watch a Video Demonstration below

RAD’s high-efficiency HAMMER Mills are made of 56 RHC carbon steel.

These mills are capable of handling 1.5 to 21.5 tons/hr.

Download the complete

Product Sheet

The 22 Series is a high speed, mid-range production, full circle screen hammer mill designed for efficiently processing agricultural products, feed and grain, light wood waste, and other relatively easy to grind materials.

Download the complete

Product Sheet

Watch a Video Demonstration below

The 44 Series hammer mill is designed for very high production grinding of agricultural products, feed and grain, light wood waste and other relatively easy to grind materials.

Download the complete

Product Sheet

Designed for R&D, pilot-scale, and small production applications, this unit boasts a capacity of 80 to 600 lbs per hour, depending on material.

Download the complete

Product Sheet

The MILL-R35 is an economical pilot-to-production scale ring die pellet mill that boasts a dependable belt drive system and has the capacity to produce 500 to 2500 lbs per hour, depending on the material.

Download the complete

Product Sheet

Capable of producing 3,000 to 24,000 lbs of pellets per hour, its output varies with the raw material. This versatile unit is designed for applications ranging from animal feed, and plastics, to fertilizer, and even demanding tasks like wood pellet production. With a rating of up to 200 HP, it’s your ultimate pellet mill solution.

Download the complete

Product Sheet

Capable of producing 8,000- 40,000 lbs of pellets per hour, its output varies with the raw material. This versatile unit is designed for applications ranging from animal feed, and plastics, to fertilizer, and even demanding tasks like wood pellet production. With a rating of up to 400 HP, it’s your ultimate pelletizing solution.

Download the complete

Product Sheet

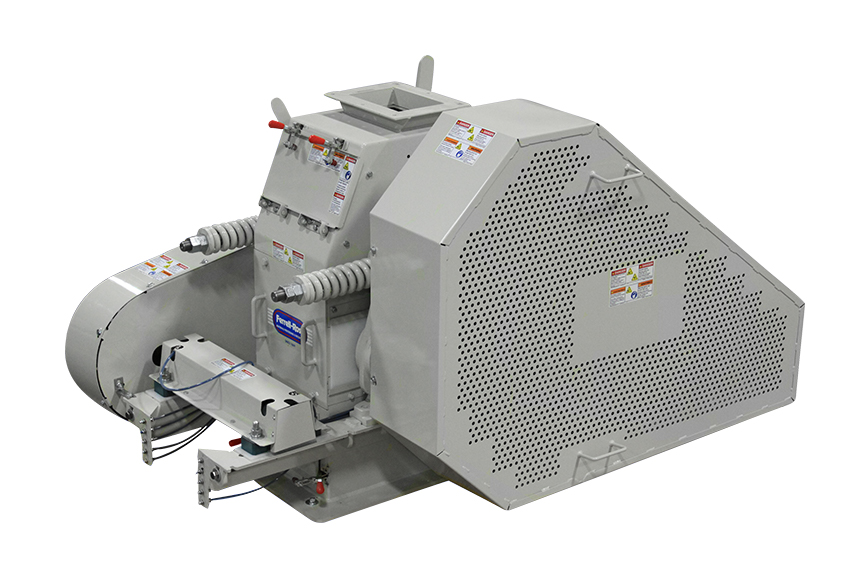

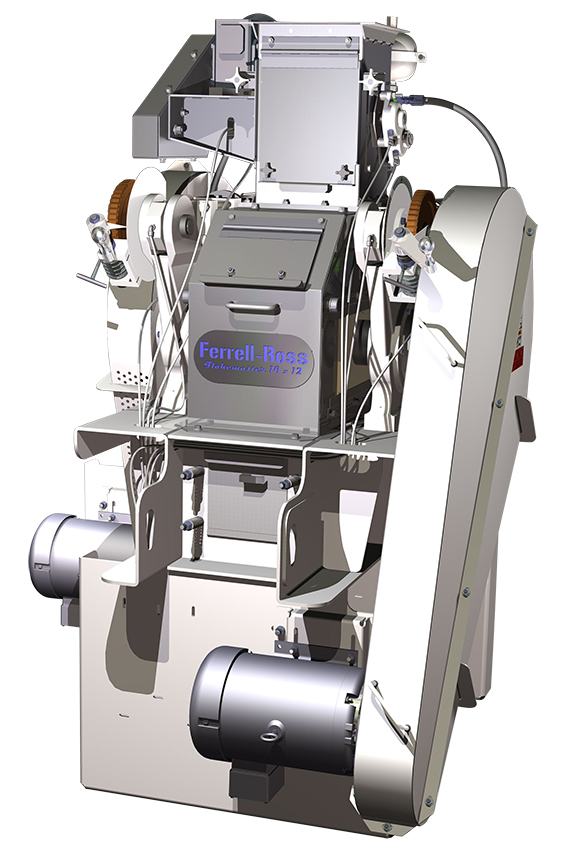

Ferrell Ross Single HI Industrial Roller Mill

The Ferrell-Ross Single-Hi Roller Mills are ideal when the finished product needs to be of a course nature.

Download the complete

Product sheet

For a finer particle reduction, the Ferrell-Ross 2 Hi or 3 Hi Industrial Roller Mills are the ideal choice

Download the complete

Product Sheet

The High Capacity 12×52 2-Hi Mill has increased drive power and faster roll speeds that provide maximum capacity in a reduced footprint design.

Capacity:

Up To 35 Short Tons Per Hour

Download the complete

Product Sheet

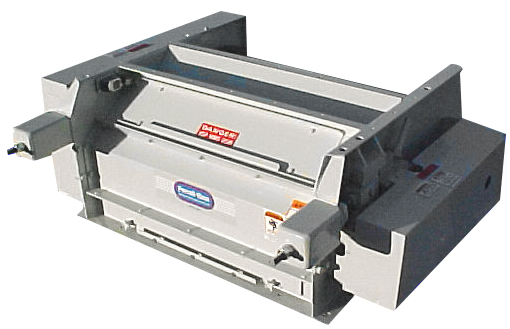

The Model “M” was developed as a scaled-down version of the industrial mill especially for customers with easy-to-grind products and low tonnage requirements.

Capacities range from

50 to 1200 BPH depending on product.

Download the complete

Product sheet

The Model “M” is available as either a single-high with one pair of rolls, or a double reduction two high with one pair of rolls mounted on top of the other. Either mill is available with a variety of roll corrugations and can be ordered with or without an inlet hopper.

Capacities range from

180 to 1200 BPH depending on product.

Download the complete

Product sheet.

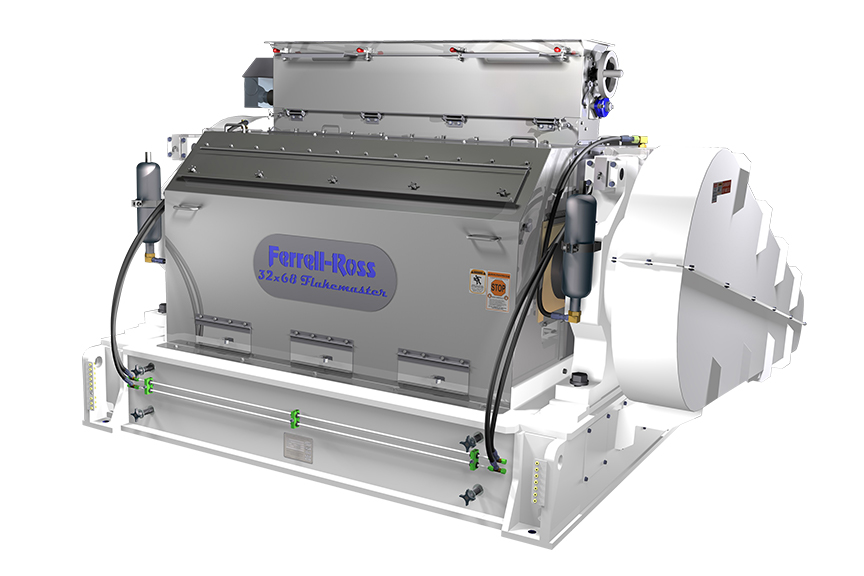

• Two Chilled Cast Iron Rolls

• Heavy Duty Mild Steel Mill Base

• T304 Stainless Steel Mill Housing

• (2) Roll Inspection Doors

• FlakeMaster Design Allows Roll Removal From Front or Back of Mill

• Heavy-Duty Spring and Hydraulic Accumulator Roll Protection

• Double Row Self-Aligning SKF Spherical Roller Bearings • Hydraulic Cylinder Roll Tension

Download the complete

Product sheet

• Dual 60 HP drives provide ample power for even the most demanding cereal flaking applications.

• Improved roll scraper (mill knife) location and adjustment allow for fine tuning of the blade angle and point of roll contact.

• Re-designed roll guards meet safety guidelines while allowing access to roll scraper adjustments and knife warping bolts.

• Improved roll alignment and roll gap precision.

Available in 2 Sizes: 24 x 36 and 32 x 40

Download the complete

Product sheet

Ferrell-Ross Steam Chests provide the proper retention time required to produce high quality flakes. Built to match your specific capacity needs, each Ferrell-Ross Steam Chest is constructed from 10 gauge 304 stainless steel for maximum longevity. Precisely placed steam injection rings improve steam efficiency and steep cone transitions allow the high moisture material to flow evenly.

Steam Chests are available in 38”, 48”, 66”, and 84” diameters.

Download the complete

Product sheet

Ferrell-Ross Crumblers are designed to break pellets into smaller particles. Most Crumbler applications align the crumbler directly below a Pellet Cooler. The output from the crumbler can be routed to a separating screener for classification or to another processing component.

Download the complete

Product sheet

The RC Flake and Pellet Coolers are designed for continuous flow cooling with eccentric driven baffles that prevent product bridging.

Download the complete

Product sheet

Ferrell-Ross Roll Feeder Conversions are available to replace vibratory feeders on Ferrell-Ross and multiple other brands of flaking and roller mills.

Download the complete

Product sheet

The Ferrell-Ross Granulizer reduces the clumping of cracked material in an Oil Seed Flaking Process

Download the complete

Product sheet

This 18 x 12 Laboratory Feed Flaking Mill is designed to be the ideal mill for today’s foundation sized or laboratory steam flaking process (up to 2 tons per hour)

Download the complete

Product sheet

This 18 x 12 Laboratory Oil Seed Flaking Mill is designed to be the ideal mill for today’s foundation sized or laboratory steam flaking process (up to 2 tons per hour)

Download the complete

Product sheet

This 18 x 12 Laboratory Cereal Flaking Mill is specifically designed for laboratory, pilot plant or foundation sized cereal flaking processes (up to 150 lbs. high capacity flaking mills. per hour).

Download the complete

Product sheet

This 18 x 12 Laboratory Oat Flaking Mill is specifically designed for laboratory, pilot plant or foundation sized oat flaking processes (Up to 2,500 lbs./hr.).

Download the complete

Product sheet

The Ferrell-Ross 18×6 Laboratory Flaking Mill is extremely versatile and an ideal choice for laboratory, R & D or pilot plant settings. With the inverter duty motors and controls you can easily change roll speed and differential often required for laboratory and R & D applications by simply adjusting the inverter setting.

Download the complete

Product sheet

By properly placing magnetic separation at strategic locations, you can greatly reduce the risk and liability of metal contamination in your final product.

Ferrell-Ross offers magnet assemblies as an option on all its industrial roller mills.

Download the complete

Product sheet

RAD’s high-efficiency Roller Mills are made of 57 Rockwell hardened steel.

These mills are capable of handling 1.5 to 7.0 tons/hr.

Single pair rollers or stacked

Download the complete Product Sheet